The Group

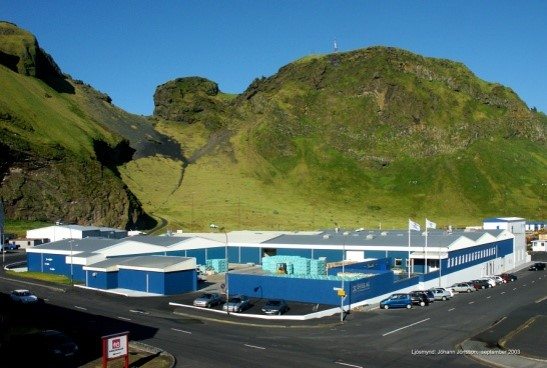

Founded in 1901, Isfelag stands as a one of the cornerstones of the Icelandic seafood industry, operating five processing units across Iceland and own fleet of vessels. Its facilities include a fishmeal factory and a freezing plant in Vestmannaeyjar, along with another fishmeal factory and freezing plant in Thorshofn. In Siglufjordur, Isfelag run a specialized peeling plant, processing coldwater shrimp.

Brim is one of Iceland’s largest and most dynamic seafood operators. With a fleet of six advanced groundfish trawlers, including three freezing trawlers and three fresh fish trawlers, Brim ensures a steady supply of premium seafood to its groundfish plant in Reykjavik. In its pelagic operations, Brim operates three specialized vessels, bringing fresh fish to its land-based processing facilities in Vopnafjordur, where it’s processed for freezing, fishmeal, and high-quality fish oil.

Founded in 1946, Skinney-Thinganes is a leader in the fishing industry, renowned for its diverse operations. Skinney-Thinganes runs three factories, including a fishmeal factory in Höfn, a versatile processing plant in Höfn specializing in pelagic fish, groundfish, and a groundfish processing facility in Þorlákshöfn. Skinney-Thinganes own fleet of vessels featues two pelagic vessels, three fresh fish trawlers, and a longliner.

Iceland Pelagic was established in 2008 by key players in the Icelandic pelagic fishing and processing industry as a sales unit with the main focus on pelagics for Eastern Europe. Since then, Iceland Pelagic has been expanding its product portfolio and market area and is now one of the main exporters of seafood from Iceland.